Our portfolio

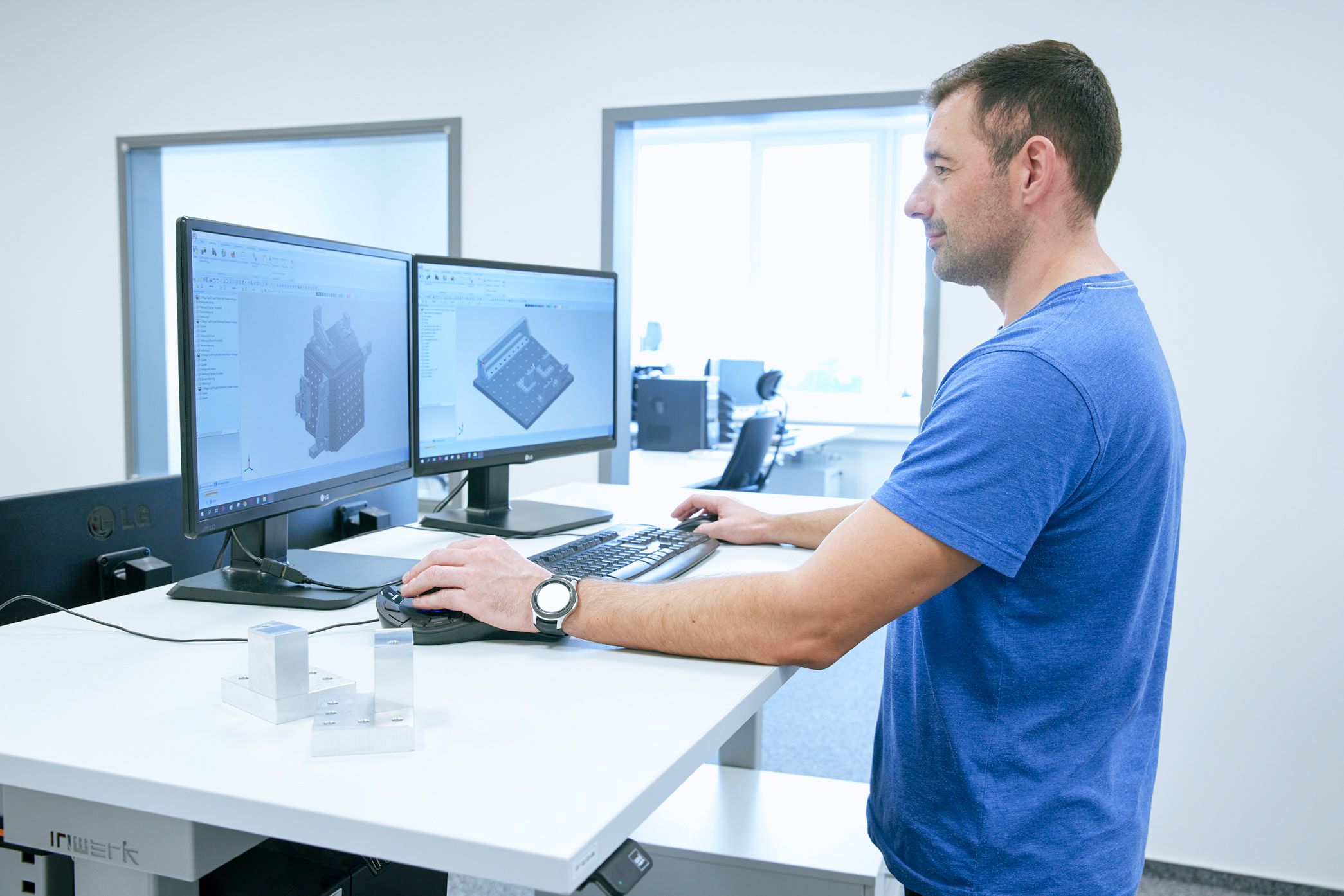

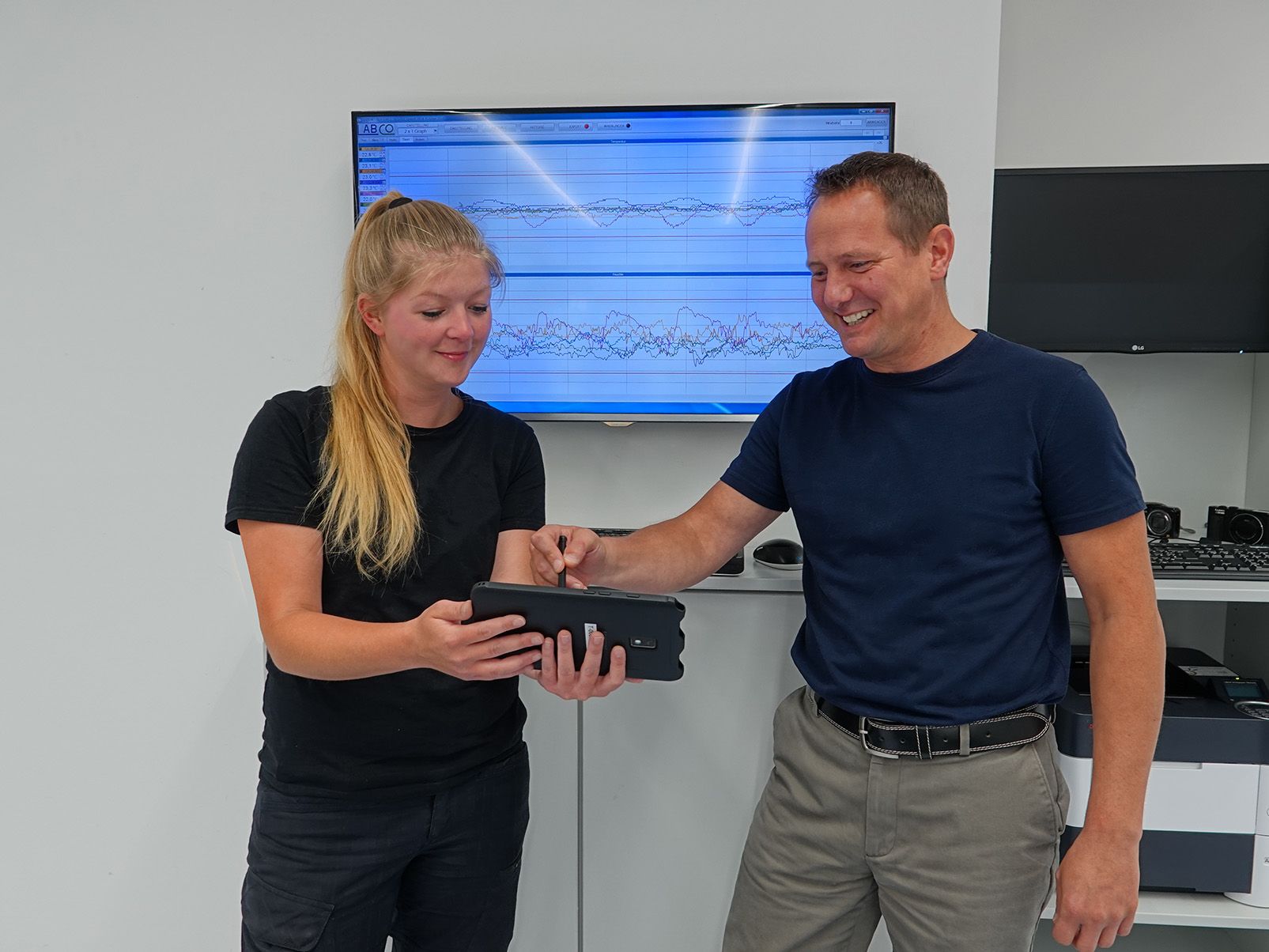

Our key competence is to test and examine electrical automotive system components such as cables, plug-in and protection systems, but also batteries. In addition, we perform tests on products and components from household and building technology, aerospace and agricultural machinery technology and other industries.

We know that high demands are placed on your product on the way to approval, such as reliability under extreme environmental influences. We accompany you on this path – and test and analyse your components as required. We will find a suitable solution for your test request.

- Approval tests

- Benchmark analyses

- Development of new testing standards

- Indiviual tests and analyses

- Development of innovative test methods

Approval tests

We test your products according to national, international and OEM standards or individual specifications. Our test reports are officially recognised by OEMs so that you can go into production without any further ado after a successful test by LABCO.

Benchmark analyses

What are potentials of your product? We perform tests and analyses on your selection of products and provide you with extensive data for your decisions.

Development of new testing standards

Innovative products require appropriate testing standards. We are involved in various national and international committees to develop new testing standards for current and future product solutions.

Indiviual tests and analyses

We gain in-depth insights into the behaviour of your test specimens or samples, for example with the help of our various microscopes or material analyses options.

Development of innovative test methods

You want to launch a new product on the market, test it for new requirements or are struggling with product failures in application? We work with you and your customer to develop test scopes that are required for market launch or develop test methods together with you that provide reliable information on the new requirements and failure cases.

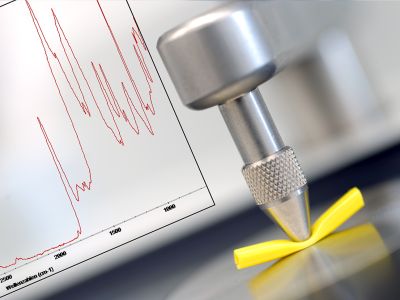

- Differential scanning calorimetry (DSC)

- Thermogravimetric analysis (TGA)

- Fourier-transform infrared spectroscopy (FTIR)

- Melt Flow Rate (MFR) / Melt Volume Rate (MVR)

- X-ray fluorescence spectroscopy (XRF)

- Etc.

We primarily use our extensive material analysis capabilities to determine the properties of both polymeric and metallic materials. For example, we can determine the thermal material properties, such as the melting temperature, but also the structural characteristics of the materials, such as the molecular composition of plastics or the layer thicknesses of metallic materials. The results of the analyses can be used to gain a better understanding of the materials used in your products and their behaviour under different conditions.

- High-voltage tests up to 50 kV

- High resistance measurements up to the TΩ range

- Precision resistance measurements up to the µΩ range

- Power supplies with currents up to 3000 A

- Derating

- Electrical properties during water storage

- Short circuit tests

- Withstand voltage

- Individually designed current cycle tests

- Tests on battery cells, modules and packs, e.g.:

- Charging and discharging

- Overcharging

- All tests can be performed under a wide range of climatic and thermal conditions.

- Etc.

Electrical tests are performed, among other things, to check the safety and integrity of an electrical system. For example, we use our high-voltage devices to test the withstand voltage of a wide variety of insulating materials. We use various resistance measuring devices to determine resistances from a few µΩ up to several TΩ.

- Two tensile testing machines, with laser-supported optical extensometers for testing tensile stress, elongation at break and tear resistance of plastics as well as bending forces, sliding forces, peeling forces, notch resistance and flexibility of cables.

- Micro hardness tester

- Shore hardness tester

- Abrasion testing machines with needle (3 different types) for cables, adhesive tapes and protection systems

- Sandpaper abrasion machine

- Abrasion cable against cable

- Special abrasion machine for corrugated pipes and protective systems

- Winding tests with rotating mandrel (motor-driven) at room temperature as well as in the cold chamber at up to -70°C

- Bending tests from -40°C to 180°C

- Torsion test bench for cables

- Drop test drum

- Slow-motion tests up to approx. 220°C

- Door slam tests in the climatic cabinet (special situations can be simulated)

- Chassis simulation tests in the climatic cabinet (standardised or application-related)

- Fretting corrosion

- Impact tester for protection systems

- Etc.

By using of our extensive selection of mechanical testing methods, we determine the mechanical properties of your components or individual materials. Our modern equipment enables us to perform both quasi-static and dynamic mechanical tests for you.

- Salt spray tests

- Compatibility with chemical operating materials, chemical resistance (petrol, oils, acids, bases, …)

- Compatibility with cable harness components

- Water tightness tests (IPX chamber, negative and positive pressure)

- Transport simulation of connector housings

- Temperature shock chamber in air (-80 °C to 220 °C)

- Temperature shock chamber in liquid (-40 °C to 170 °C)

- Moisture content determination

- Fogging test

- Ozone tests

- Hydrolysis tests (water storage)

- Laboratory for flame tests, e. g. burning behaviour

- Climatic and temperature aging / storage

- Etc.

To ensure the functionality of your product over time, we can expose your components to a variety of environmental conditions. This includes tests such as temperature cycling, vibration, shock, humidity and other tests that ensure your products meet your customers’ requirements. Our tests also help you improve the performance and reliability of your products by simulating and analysing the effects of potential environmental influences on the functionality of your products.

- Over 40 climate and temperature cabinets

- Temperature shock chamber air

(-80 °C to 220 °C) - Temperature shock air – liquid

- Three walk-in temperature and climate chambers (11, 5 m³ test chamber volume)

- Temperature range: -45°C to 150 °C

- Humidity range: 10 % to 95 % RH

- Etc.

We perform thermal and climatic tests to determine, for example, the heat, moisture and cold resistance of various materials, components and systems. Usually, these tests are specified within narrow limits in OEM standards, but also international standards. Thermal and climatic tests are often performed as long-term tests. They are therefore an essential indicator of the long-term temperature resistance of the components and materials we test.

- Video microscopy

- Stereomicroscopy

- Digital microscopy with a magnification of 0 – 200x and a depth of field of 4 cm

- Upper and lower light microscope (for homogeneity examinations)

- Fully automatic microscopic measuring device for cables and wires

- Microtome (we can separate foils with a thickness of approx. 2 µm from plastics)

- Optical 3D profilometer

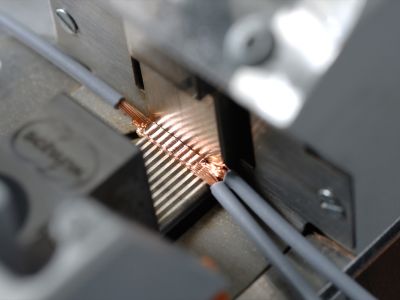

- Microsection laboratory for measuring crimp contacts

- Etc.

Microscopic examinations are used to study the structure, morphology, distribution, size and shape of materials. These examinations can be applied to all types of materials such as metals, polymers, ceramics and other inorganic and organic substances. Our range includes fully automated methods for determining the size of cables and wires as well as manual measurements using a microscope, for example to examine surface structures and crimp contacts.

- Network analysers (5 Hz to 26.5 GHz)

- Triaxial measuring tubes (40 mm and 90 mm diameter)

- Measuring instruments for line feed

- Examples of measurement possibilities:

- Return and insertion loss

- Measurement of characteristic impedance

- Measurement of shielding effectiveness, e.g.

- Measurement of screening attenuation

- Transfer impedance

- Coupling attenuation

- Line symmetry

- Etc.

For radio frequency tests, specific electrical signals are used to examine an object or component for defects, damage, or deviations from the standard. We perform measurements for all common cable configurations. All measurements can be combined with load tests, if necessary. We also check components that are not intended for high-frequency use, but whose behaviour at high frequencies must be known. This includes high-voltage plug connectors, filters, distributors and sensor cables.

- Extraction test equipment

- Test equipment for various chemical tests, e. g. storage in

- Oil

- Fuels

- Battery acid

- Other liquids and chemicals

- Laboratory for flame tests, e. g. burning behavior

- Etc.

Chemical tests determine the chemical properties of a material or substance. They can be used to determine the identity, purity, concentration and other properties of a substance. Chemical tests can include a simple visual inspection, a chemical analysis, a chromatographic examination or a spectroscopic analysis. We mainly perform tests to determine the properties of a part when in contact with various operating fluids and for burning behaviour.

- Door slam tests

- Micro hardness tester

- Shore hardness tester

- ABS simulation test equipment

- Slow-motion tests (up to 220 °C)

- Flexural strength (-40 °C to 180 °C)

We perform individual tests in direct consultation with you. For this purpose, we use our own test equipment or develop completely new test set-ups for you, e.g. to simulate special loads on the components during application. We are happy to use the know-how at LABCO, which we have built up over decades, to realistically simulate the stress on your components using individual test set-ups or test parameters.

Technical data of the shakers:

Shaker 1:

- Sine force: 50 kN

- Shock force: 100 kN

- Temperature range: -70 °C to 180 °C

Shaker 2:

- Sine force: 80 kN

- Shock force: 160 kN

- Temperature range: -70 °C to 180 °C

Shaker 3 + 4:

- Sine force: 300 kN

- Shock force: 900 kN

- Temperature range: -45 °C to 150 °C

Many components in vehicles or other moving systems are exposed to constant vibrations and temperature variation as well as climatic changes. With our four vibration test systems (shakers) we have the possibility to apply dynamic vibration and shock loads to components of various sizes. The mechanical load on the components can be overlaid with defined temperatures or climatic conditions. In this way, we determine the durability of your components and systems under extreme conditions.

Performance or battery tests are designed to test the performance of a device or battery, module or pack. Our tests can be used to determine the performance, efficiency and capacity of a device or battery, as well as its charging behaviour. We can also examine the response to external stimuli or environmental influences, the durability and the reliability of batteries.

Didn’t find what you are looking for?

Contact us! We will be happy to advise you and show you further analysis and testing options, which are not explicitly shown for the sakeof better overview.